Analyze Your System (Analyze Tab)

Time to review: 2-3 minutes

View calculation results, product carbon footprints, and emission breakdowns.

What is the Analyze Tab?

The Analyze tab displays the calculated results of your system after you've completed data entry. Here you'll see:

- Product-level carbon footprints for all outputs

- Emission breakdowns by source, sink, and credits

- Visual analysis tools (Sankey diagrams, bar charts)

- System performance metrics

Requirement: Your system must have "Ready" status to see complete results.

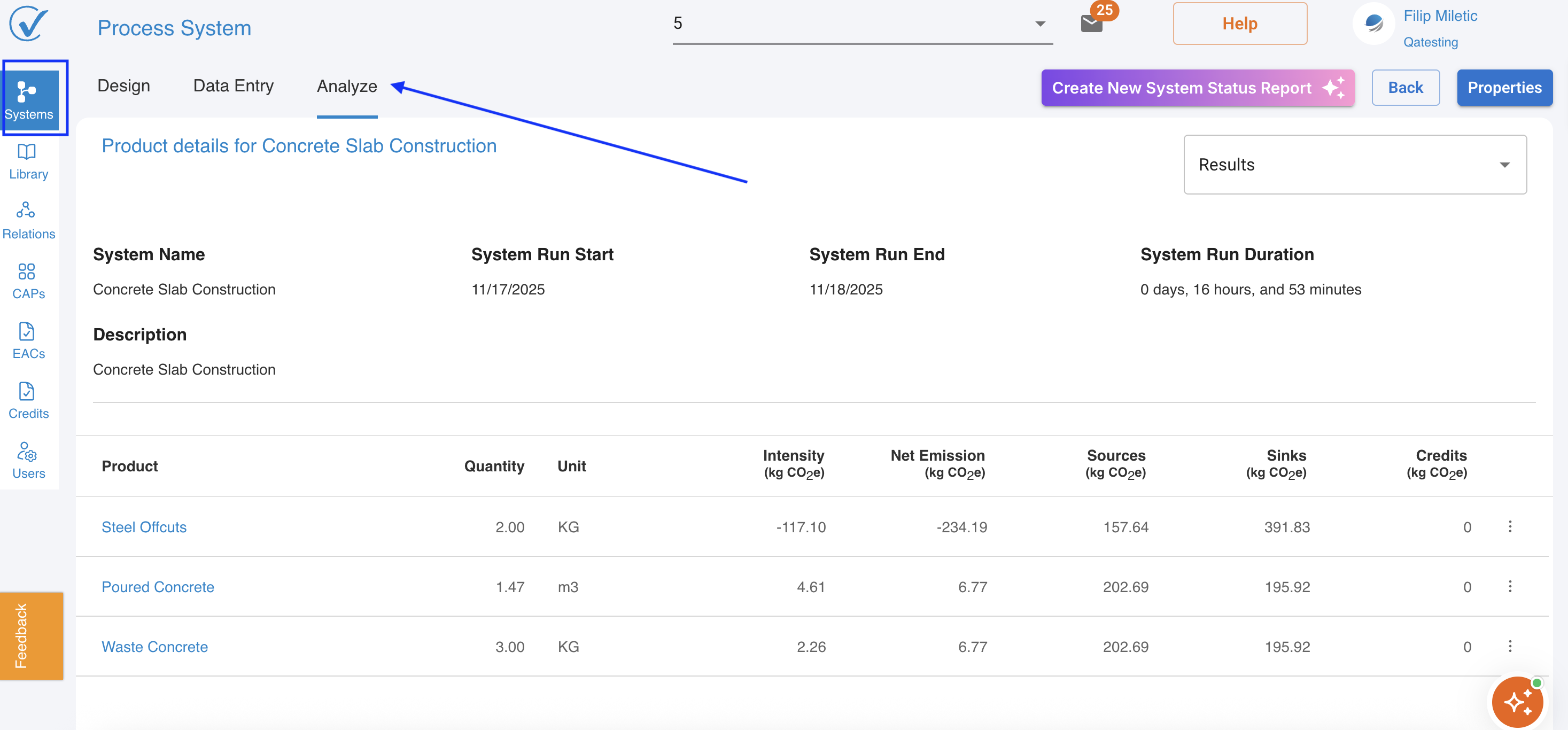

Understanding the Results View

System Information Panel

At the top of the page, you'll see key system details:

- System Name - Your system's identifier

- System Run Start/End - The time period covered by calculations

- System Run Duration - How long the system represents (days, hours, minutes)

- Description - Your system's purpose and scope

Product Results Table

The main table shows carbon footprint calculations for each output product:

| Column | What It Shows | Example |

|---|---|---|

| Product | Output name from your system | "Steel Offcuts", "Poured Concrete" |

| Quantity | Amount produced | 2.00 |

| Unit | Measurement unit | KG, m3, tonnes |

| Intensity (kg CO₂e) | Carbon per unit of product | 4.61 kg CO₂e/m3 |

| Net Emission (kg CO₂e) | Total emissions after sinks and credits | 6.77 kg CO₂e |

| Sources (kg CO₂e) | Total emissions generated | 202.69 kg CO₂e |

| Sinks (kg CO₂e) | Carbon removed or sequestered | 195.92 kg CO₂e |

| Credits (kg CO₂e) | Offsets applied | 0 |

Understanding Emissions Calculations

How Net Emissions Are Calculated

Net Emission = Sources - Sinks - Credits

Example from the table:

- Poured Concrete (1.47 m3)

- Sources: 202.69 kg CO₂e (all emissions generated)

- Sinks: 195.92 kg CO₂e (carbon absorbed/removed)

- Credits: 0 kg CO₂e (no offsets applied)

- Net Emission: 6.77 kg CO₂e (final footprint)

- Intensity: 4.61 kg CO₂e/m3 (per unit)

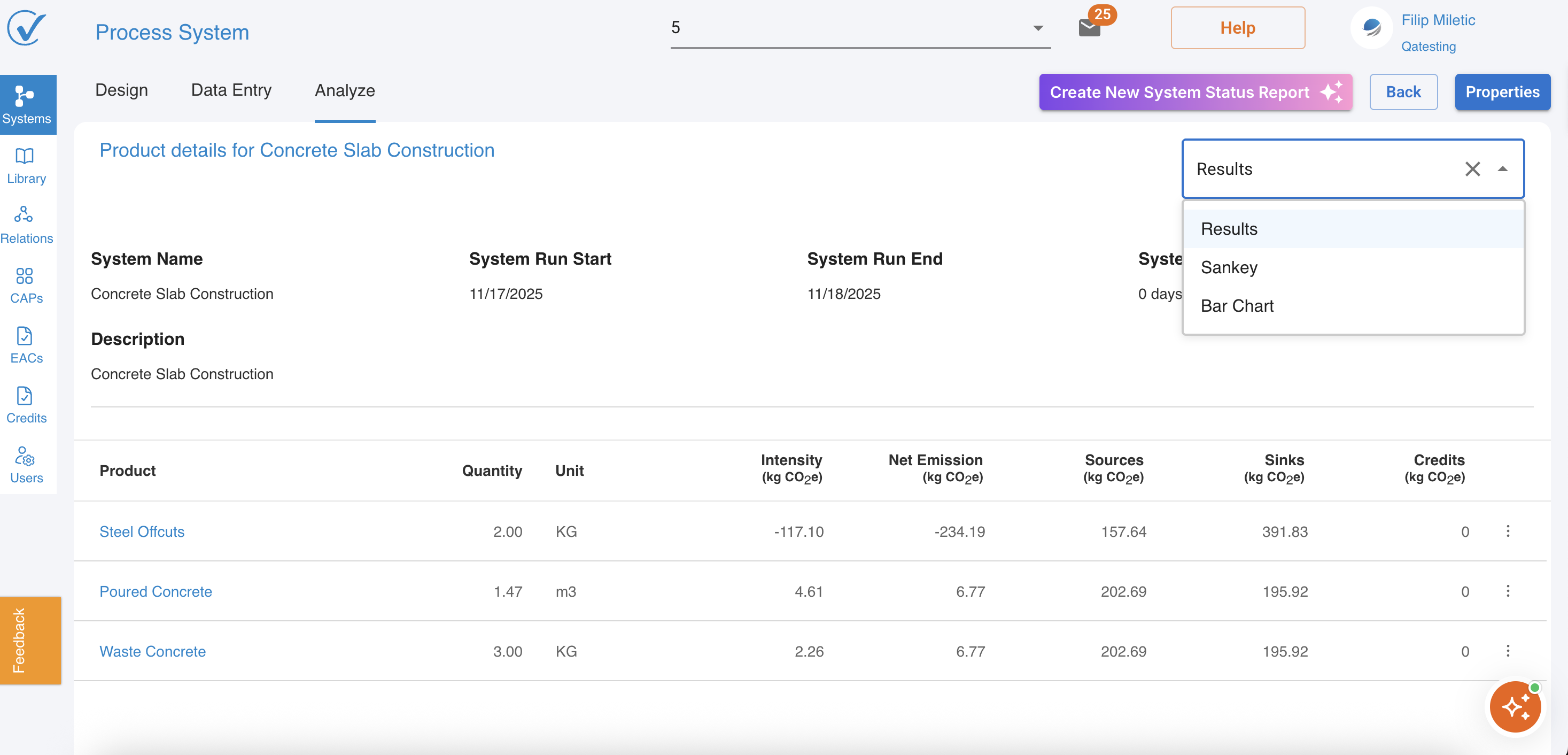

Accessing Visualization Tools

Results Dropdown Menu

Click the "Results" dropdown in the top-right to access analysis views:

Available Views:

- Results - Default table view (shown above)

- Sankey - Carbon flow diagram showing emission pathways

- Bar Chart - Ranked contributors to total emissions

Dropdown showing Results, Sankey, Bar Chart options

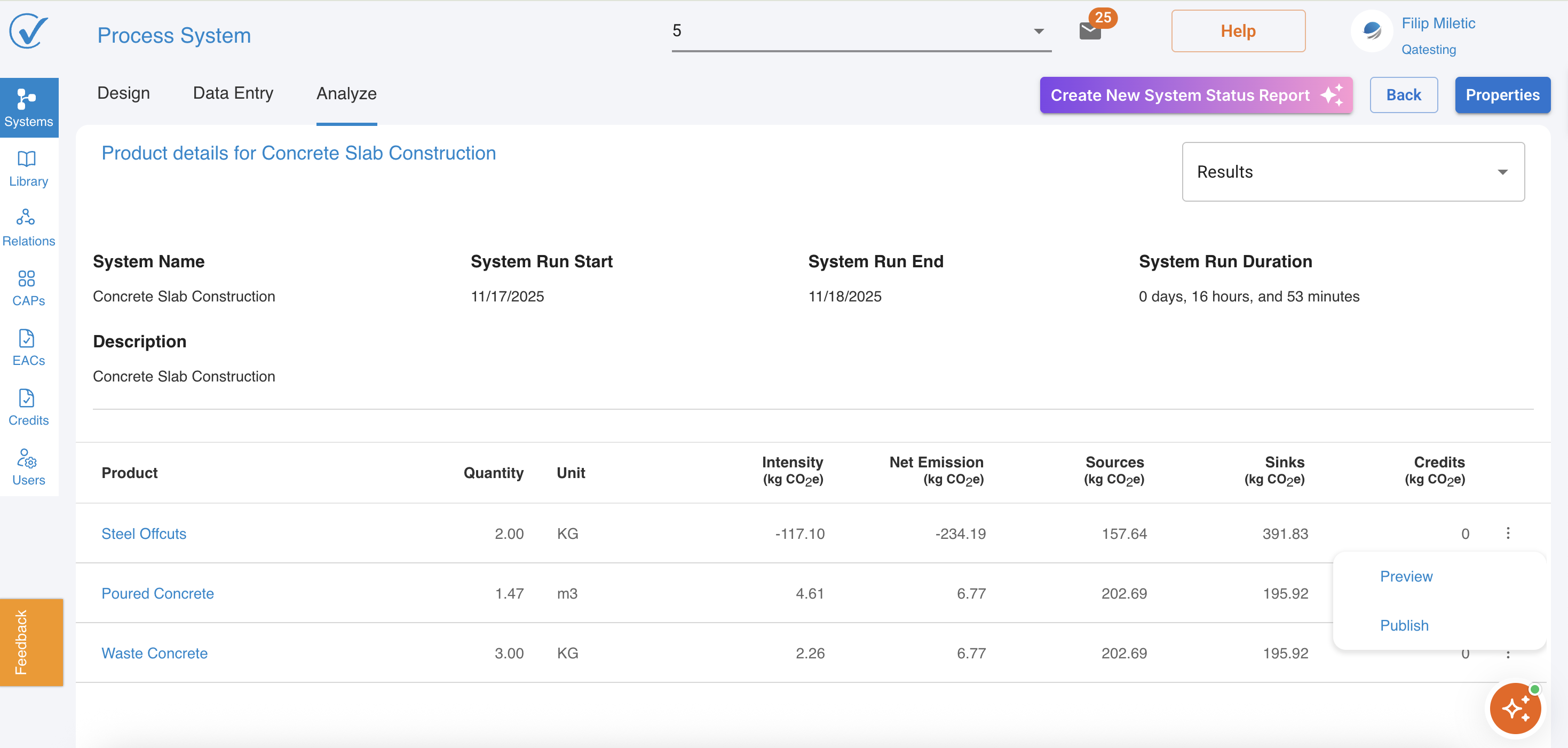

Product Actions Menu

Each product row has an actions menu (⋮) with options:

Preview

- Opens a detailed view of the product's carbon footprint

- Shows complete emission breakdown by scope and process

- Useful for reviewing before publishing

Publish

- Creates a Carbon Attested Product (CAP)

- Makes the carbon footprint official and shareable

- Moves to CAPs page for distribution

💡 Tip: Always preview results before publishing to verify accuracy.

When to Use Analyze Tab

Review after data entry:

- Verify all calculations are correct

- Check for unexpected emission values

- Identify highest-impact products

Before generating CAPs:

- Ensure results meet your quality standards

- Validate emission intensities are reasonable

- Review scope classifications

For reporting:

- Extract carbon footprint data

- Generate visual aids for presentations

- Support sustainability disclosures

Interpreting Negative Intensities

Example: Steel Offcuts (-117.10 kg CO₂e/KG)

Negative carbon intensity indicates:

- Product sequesters more carbon than it emits (sinks > sources)

- Common for by-products that avoid primary production

- Allocation credits from waste recovery

- Carbon removal or recycling benefits

Why this happens:

- Steel offcuts avoid virgin steel production

- Recycling credits allocated to the by-product

- System boundaries include avoided emissions

Common Result Patterns

High Sources, Low Net Emissions

- Indicates significant sinks or credits applied

- Check if allocation is appropriate

- Verify sink/credit data is accurate

Similar Intensity Across Products

- May indicate shared upstream processes

- Check allocation methodology

- Consider if products should have distinct profiles

Zero Credits Column

- No carbon offsets have been applied

- Credits are optional and added separately

- Contact your admin to apply organizational credits

Quick Actions Reference

| I want to... | Do this... |

|---|---|

| View detailed breakdown | Click product name or Preview |

| Create CAP | Click ⋮ menu → Publish |

| See emission flows | Results dropdown → Sankey |

| Identify hotspots | Results dropdown → Bar Chart |

| Check calculation basis | Review Sources, Sinks, Credits columns |

| Verify time period | Check System Run Start/End dates |

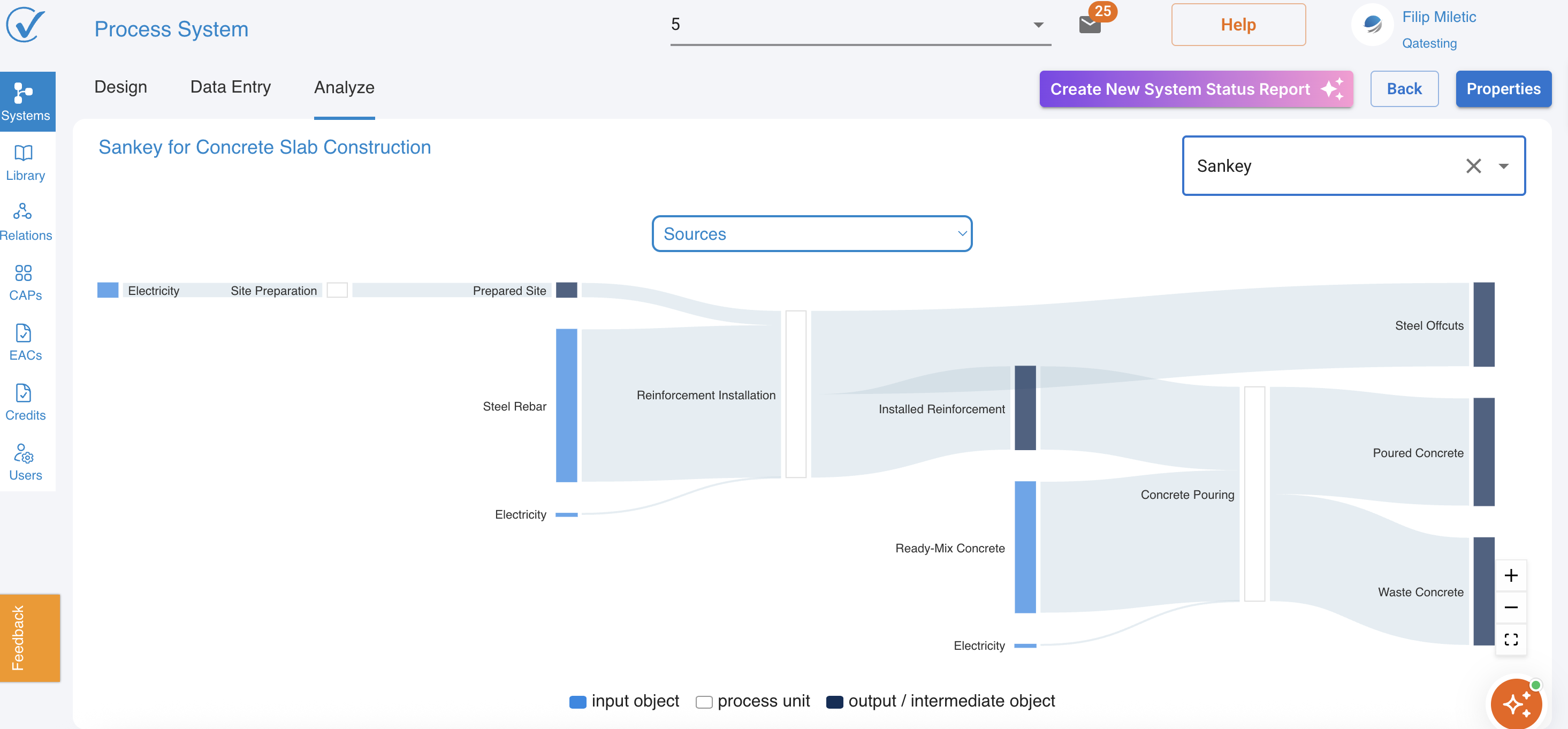

Sankey Diagram View

The Sankey diagram visualizes carbon flows through your system, showing how emissions travel from inputs through processes to final outputs.

Accessing Sankey View

- Click the "Results" dropdown (top-right)

- Select "Sankey"

- The diagram displays your complete system flow

Understanding the Sankey Diagram

Visual Elements

The Sankey uses three visual components:

| Element | Color | Represents |

|---|---|---|

| Input objects | Light blue | Materials and energy entering processes |

| Process units | Light gray boxes | Activities that transform inputs |

| Output/Intermediate objects | Dark blue/gray | Products and co-products |

Flow width indicates emission magnitude - wider flows = higher emissions

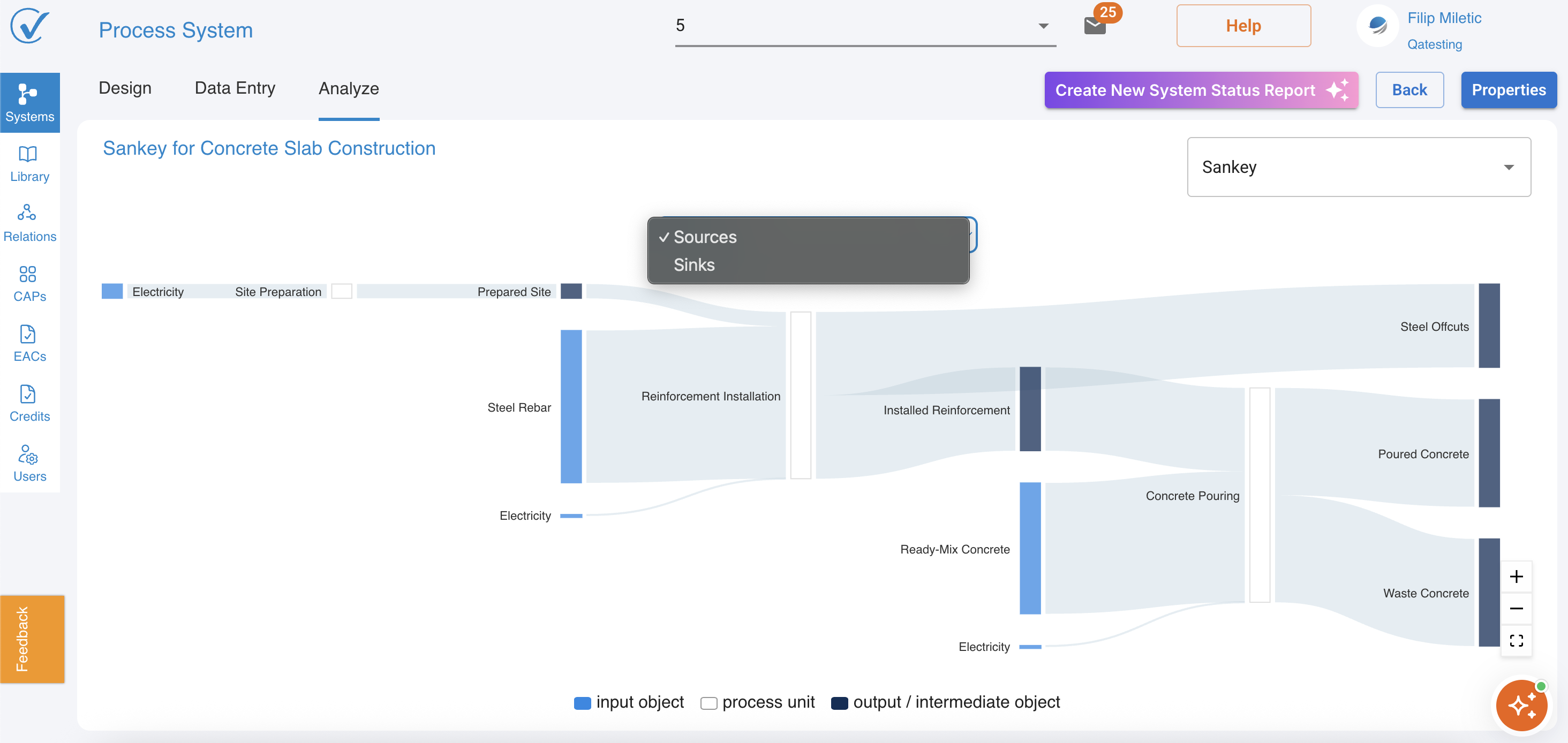

Switching Between Sources and Sinks

Options:

- ✓ Sources (default) - Shows emission generation

- Sinks - Shows carbon removal

Why separate views:

- Carbon flows in opposite directions (emission vs. sequestration)

- Prevents visual overlap and confusion

- Allows focused analysis of each aspect

- Clarifies accounting methodology

💡 Pro tip:

- Review Sources first to identify emission hotspots

- Switch to Sinks to find offset opportunities

- Compare magnitudes to understand net carbon position

Important: Sources and Sinks cannot be displayed simultaneously in the same Sankey diagram.

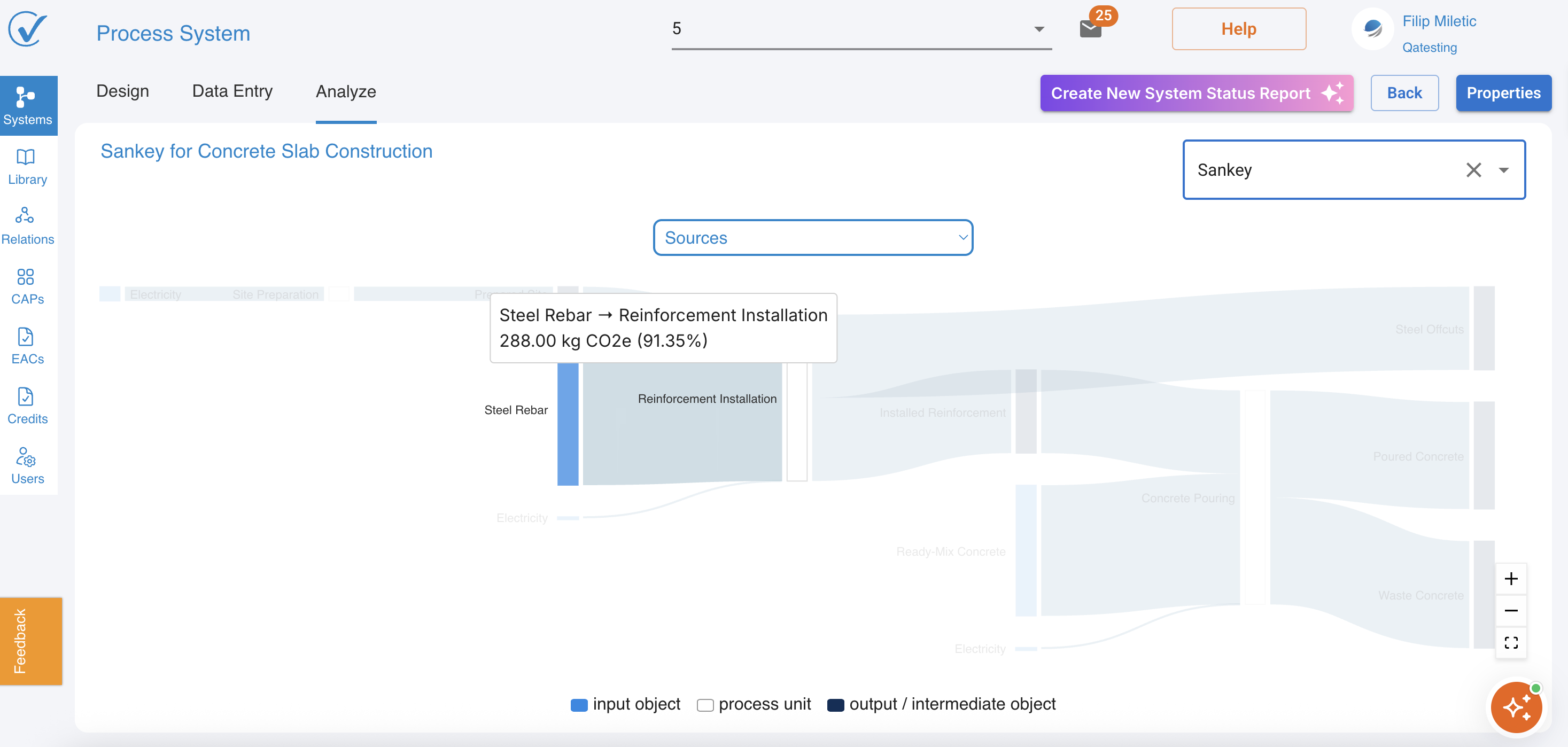

Sources View (Default)

Shows emissions generated by the system:

What you see:

- Blue input flows representing emission sources

- Process units showing transformation steps

- Output products on the right side

- Flow size proportional to CO₂e emissions

Example from Concrete Slab Construction:

- Electricity (light blue) → Site Preparation → Prepared Site

- Steel Rebar (large blue flow) → Reinforcement Installation → Installed Reinforcement

- Ready-Mix Concrete (large blue flow) → Concrete Pouring → Poured Concrete

- Electricity (small flows) → Various processes

💡 Reading the diagram:

- Larger flows indicate higher-emission inputs

- Multiple processes show system complexity

- Final outputs (right side) show product destinations

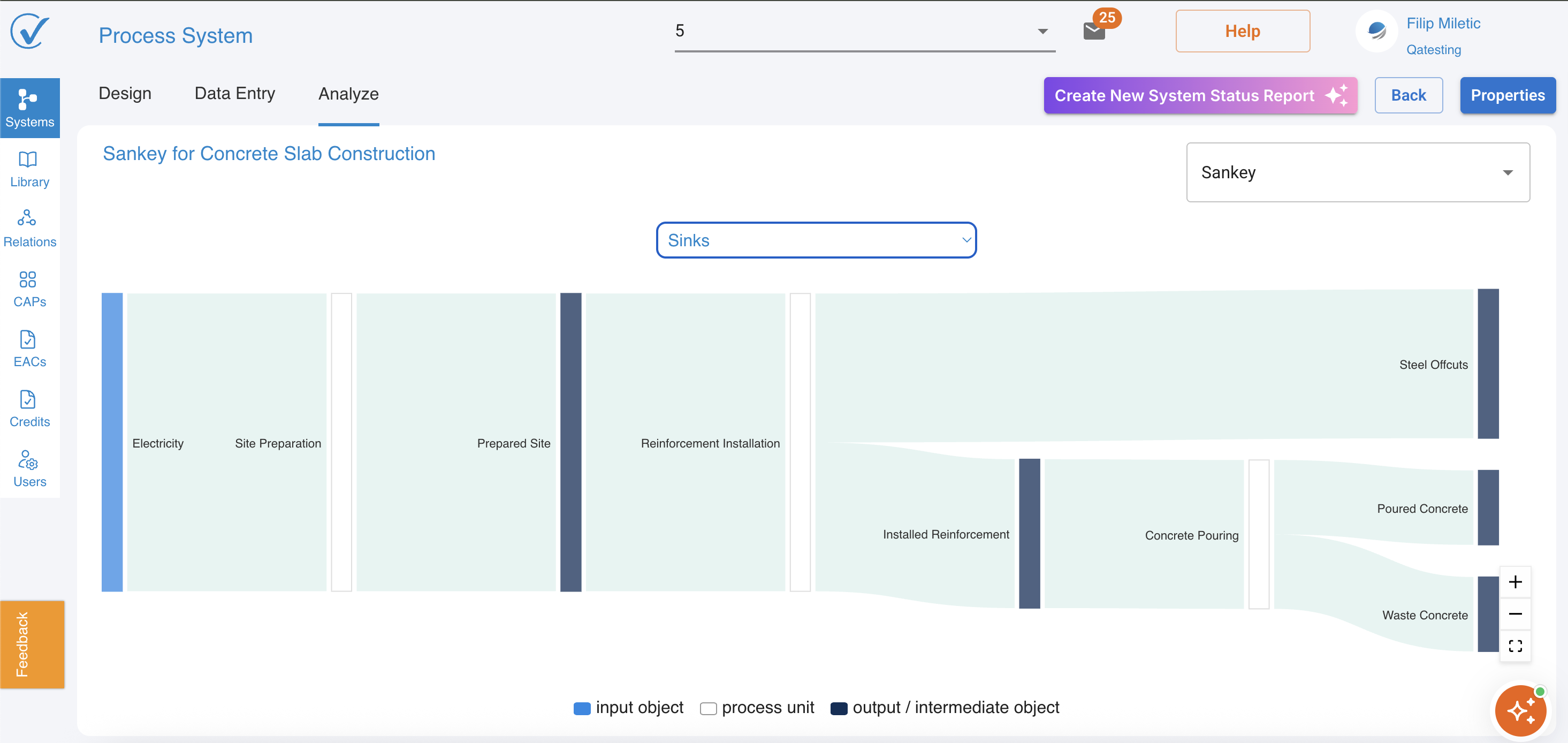

Sinks View

Shows carbon removed or sequestered by the system:

To switch to Sinks view:

- Look for the dropdown menu above the diagram

- Click to expand (shows "✓ Sources" with "Sinks" below)

- Select "Sinks"

What changes:

- Flow colors shift to show carbon removal

- Only processes with carbon sinks display flows

- Diagram simplifies to show sequestration pathways

- Flow sizes represent carbon removed (kg CO₂e)

Example from Concrete Slab Construction:

- Electricity (light blue) → Site Preparation (shows minimal sink activity)

- Most processes show no sink flows (indicated by empty/light gray areas)

- Installed Reinforcement → Shows significant carbon sequestration (large teal flow)

- Final outputs reflect net carbon removal benefits

Why Sinks are separate:

- Sources and Sinks flow in opposite directions (emission vs. removal)

- Combining would create visual confusion

- Separate views clarify carbon accounting methodology

- Allows focused analysis of emissions vs. removal strategies

Sankey Diagram Controls

Zoom and Navigation

Located in bottom-right corner:

| Control | Function |

|---|---|

| + | Zoom in for detail |

| − | Zoom out for overview |

| ⤢ | Reset to default view |

💡 Tip: Zoom in to read small process labels or analyze minor flows

Interpreting Flow Patterns

Bottleneck Identification

Wide flows entering processes = High-emission inputs

- Steel Rebar → Reinforcement Installation (largest blue flow)

- Ready-Mix Concrete → Concrete Pouring (second largest flow)

Action: Focus reduction efforts on these major contributors

Process Complexity

Multiple converging flows = Complex processes with many inputs

- Concrete Pouring receives Ready-Mix Concrete + Electricity

- Shows interdependency of materials and energy

Action: Consider process efficiency improvements

Parallel Pathways

Multiple processes operating simultaneously:

- Site Preparation happens while Reinforcement Installation proceeds

- Shows system parallelization

Action: Optimize scheduling to reduce peak emissions

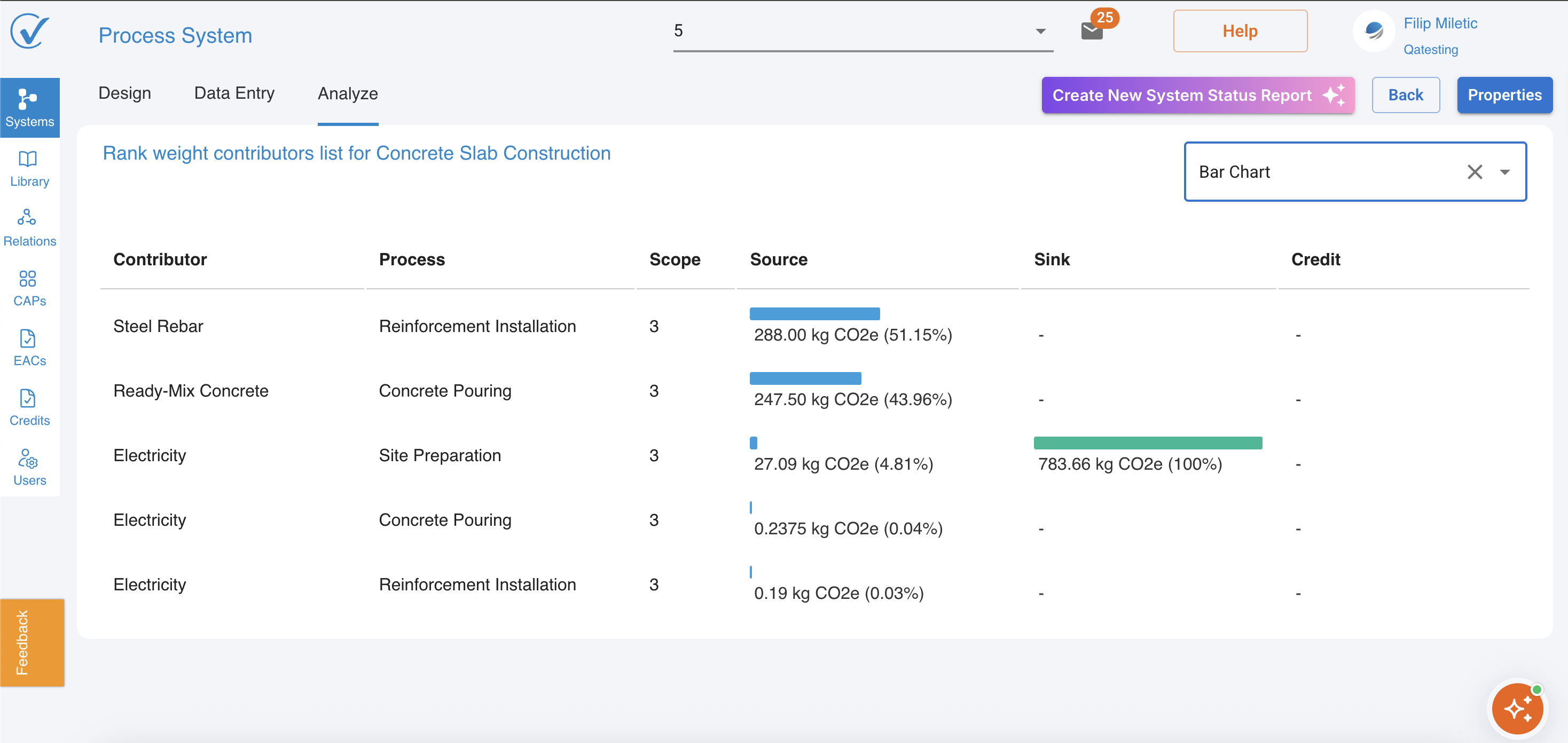

Bar Chart View

The Bar Chart ranks contributors by emission magnitude, making it easy to identify hotspots.

Accessing Bar Chart View

- Click the "Results" dropdown (top-right)

- Select "Bar Chart"

- The table displays ranked contributors

Understanding the Bar Chart

Column Definitions

| Column | What It Shows | Example |

|---|---|---|

| Contributor | Input or material name | "Steel Rebar", "Ready-Mix Concrete" |

| Process | Where the contributor is used | "Reinforcement Installation", "Concrete Pouring" |

| Scope | Emission scope classification | 3 (upstream supply chain) |

| Source (kg CO₂e) | Emissions generated | 288.00 kg CO₂e (51.15%) |

| Sink (kg CO₂e) | Carbon removed | 783.66 kg CO₂e (100%) |

| Credit (kg CO₂e) | Offsets applied | - (none in this example) |

Reading the Visualizations

Horizontal Bars

Bar length = Contribution magnitude

- Longer bars = Higher emissions or greater carbon removal

- Percentage shows relative contribution to total

Color coding:

- Blue bars = Sources (emissions)

- Green bars = Sinks (carbon removal)

- Orange/empty = Credits (when applied)

Example Rankings:

Top Sources (Emissions):

- Steel Rebar → Reinforcement Installation

- 288.00 kg CO₂e (51.15%)

- Largest emission contributor

- Ready-Mix Concrete → Concrete Pouring

- 247.50 kg CO₂e (43.96%)

- Second largest contributor

- Electricity → Site Preparation

- 27.09 kg CO₂e (4.81%)

- Minor but consistent contributor

- Electricity → Concrete Pouring

- 0.2375 kg CO₂e (0.04%)

- Negligible impact

- Electricity → Reinforcement Installation

- 0.19 kg CO₂e (0.03%)

- Minimal contribution

Sink Analysis (Bar Chart)

When viewing sinks in the bar chart:

Example from the data:

- Electricity → Site Preparation

- Sink: 783.66 kg CO₂e (100%)

- Shows complete carbon offset for this process

- Likely due to renewable energy credits or avoided emissions

Why only one sink shows:

- Most processes in this example generate net emissions

- Only Site Preparation electricity has associated carbon removal

- Demonstrates selective application of green energy

Using Bar Chart for Decision-Making

Identify Top 3 Contributors

The 80/20 Rule: Top 2-3 contributors typically represent 80%+ of emissions

From the example:

- Steel Rebar (51.15%) + Ready-Mix Concrete (43.96%) = 95.11% of emissions

- Focus reduction efforts here for maximum impact

Scope Distribution Analysis

All contributors show Scope 3:

- Indicates upstream supply chain emissions dominate

- Direct process emissions (Scope 1) are minimal

- Purchased energy (Scope 2) is negligible

Action: Engage suppliers to reduce embodied carbon in materials

Minor Contributors

Contributors < 1% of total:

- Electricity inputs (0.04%, 0.03%)

- May not warrant immediate attention

- Focus on major sources first

Comparing Sources vs. Sinks

In Sankey Diagrams

Sources view:

- Shows complete emission pathways

- Identifies where carbon enters the system

- Helps trace emissions to origin

Sinks view:

- Shows carbon removal pathways

- Highlights offset opportunities

- Demonstrates environmental benefits

💡 Tip: Review both views to understand net carbon position

In Bar Charts

Simultaneous display:

- Sources and Sinks appear in same table

- Side-by-side comparison of generation vs. removal

- Percentage helps prioritize actions

Key insight from example:

- Source: 288.00 kg (51.15%) from Steel Rebar

- Sink: 783.66 kg (100%) from Site Preparation electricity

- Net effect depends on full system calculation

Interactive Features

Hover Details (Sankey)

Mouse over elements to see:

- Exact emission values (kg CO₂e)

- Contributor names

- Process connections

- Flow magnitudes

💡 Tip: Hover to verify visual interpretations with precise data

Visualization Best Practices

When to Use Sankey

Best for:

- Understanding system structure and flow logic

- Identifying process relationships

- Communicating with stakeholders visually

- Presenting complete life cycle flows

- Finding process bottlenecks

Example use case:

- "Show management where emissions originate and flow through our system"

When to Use Bar Chart

Best for:

- Quick identification of top contributors

- Prioritizing reduction efforts

- Data-driven decision making

- Comparing contributor magnitudes

- Detailed numerical analysis

Example use case:

- "Which 3 inputs should we focus on to reduce 80% of emissions?"

Common Patterns and What They Mean

Dominant Single Contributor

Pattern: One bar represents >50% of emissions

- Example: Steel Rebar at 51.15%

- Meaning: Single-material dependency

- Action: Investigate lower-carbon steel alternatives or reduce quantities

Balanced Distribution

Pattern: Multiple contributors at 20-30% each

- Meaning: System complexity with no clear hotspot

- Action: Holistic approach needed; optimize multiple areas

Long Tail of Small Contributors

Pattern: Many inputs each <5%

- Example: Multiple electricity entries at <1%

- Meaning: Process energy efficiency already optimized

- Action: Focus on material selection instead

Exporting Visualizations

Screenshots for Reports

Recommended workflow:

- Set Sankey zoom to optimal level

- Capture full-screen view

- Toggle to Sinks view and capture

- Capture full-screen view for Bar Chart data

- Use in presentations and reports

💡 Tip: Include both Sources and Sinks Sankey views in reports to show complete carbon story

Troubleshooting Visualizations

Sankey diagram not displaying:

- Verify system has "Ready" status

- Check that all processes have connections

- Ensure inputs have emission data assigned

- Refresh browser

Bar Chart shows unexpected rankings:

- Verify Entry mode data is correct

- Check conversion factors are applied properly

- Review allocation rules in Properties

- Confirm emission sources are appropriate

Empty Sinks view:

- Normal if system has no carbon removal processes

- Check if renewable energy or credits are assigned

- Verify sink data in Entry mode

- Some systems legitimately have zero sinks

Zoom controls not working:

- Try browser refresh

- Clear cache

- Check browser compatibility

- Use keyboard shortcuts: Ctrl/Cmd + scroll

Quick Reference: Visualization Actions

| I want to... | Do this... |

|---|---|

| See emission pathways | Results → Sankey → Sources |

| See carbon removal | Results → Sankey → Sinks |

| Find top 3 hotspots | Results → Bar Chart → Review top rows |

| Zoom in on detail | Use + control or mouse wheel |

| Reset view | Click ⤢ (fullscreen) control |

| Compare contributors | Review Bar Chart percentages |

| Trace emissions to source | Follow Sankey flows left to right |

| Identify process complexity | Count converging flows in Sankey |

Next Steps After Analysis

Your results are calculated. Now you can:

- Generate CAPs → Publish products for sharing

- Optimize system → Return to Design mode to reduce emissions

- Update data → Switch to Entry mode for refined inputs

- Create reports → Use visualization tools for stakeholders

Troubleshooting

No results showing:

- Check system status is "Ready"

- Ensure all inputs have data in Entry mode

- Verify calculations completed successfully

- Refresh page

Unexpected values:

- Review Entry mode data for errors

- Check conversion factors are correct

- Verify emission sources are appropriate

- Validate allocation rules in Properties

Can't publish product:

- Ensure you have Admin or Editor role

- Check system is in "Ready" status

- Verify all required data is complete

- Contact support if issue persists

Related: Add Data to Your System | System Status Indicators | Generate CAPs